By this point in the saga, I think we can safely say that our cruising adventure is NOT going to be like what you see on the YouTube sailing channels. So, either they are far, FAR more competent at this than we are (definitely a possibility) or they are cherry-picking what they show in their videos (also possible). The third possibility doesn’t bear thinking about: we’re cursed (I mean, it could happen-I did walk under a ladder once). Here we are, back in Brunswick. We escaped for FOUR WHOLE DAYS. Of course, it cost us an oil leak and a dead battery bank, but for one shining moment we were LIVIN’ THE DREAM, BABY!

But back here in reality, we’ve got to get stuff fixed. We’ve got four problems of varying magnitude. Let’s start small, shall we?

Remember our broken traveler? We got it ALMOST repaired but were missing a part. That part arrived and, since we are back in Brunswick, we don’t have to have it shipped somewhere. So after a little drilling and a little knot-tying and a little rigging, we are back in business. Pretty easy as boat projects go, actually.

Then, we have a(nother) leak. Kim keeps finding her clothes all wet after a rain. This is not popular in some quarters. I figured out where the leak is coming from and last week, I caulked around the base of a stanchion, hoping that would fix it without taking it all apart and off the deck. I know, I know! But a guy can dream, right? Still leaking. So today, Kim took apart the cubbies in our stateroom (she seemed quite motivated to fix this, for some reason). We undid the bolts, took the stanchion base off, cleaned it up, caulked it, and refastened it. I feel like our chances of success are greater now. We’ll know when it rains.

Third, we have an oil leak. Again. Remember the bell housing and the rear seal that was all taken apart, cleaned replaced, and put back together last week? So do we. Because it was still leaking. Here are the choices:

- Unluckily, the new rear seal was defective

- The new rear seal was damaged upon installation

- The journal of the crankshaft is corroded and causing the seal to fail

- The crankshaft bearings are worn so the crankshaft loses alignment and causes the seal to fail

So today, apart came the engine, again. The rear seal had definitely failed. You could see daylight through it-that’s definitely not going to keep oil inside the crankcase. The good news is that the crankshaft journal looks good-no evidence of corrosion or uneven wear. Our amazing team had a new seal set in place and got the engine put back together. After an hour of run time, there is NO OIL LEAK. WOOHOO!!! But, we’ll be doing some further testing before declaring victory.

Finally, we have the dead batteries. Turns out, there were all sorts of issues there.

- First, our engine alternator wasn’t charging the batteries thanks to (we think) a defective circuit breaker.

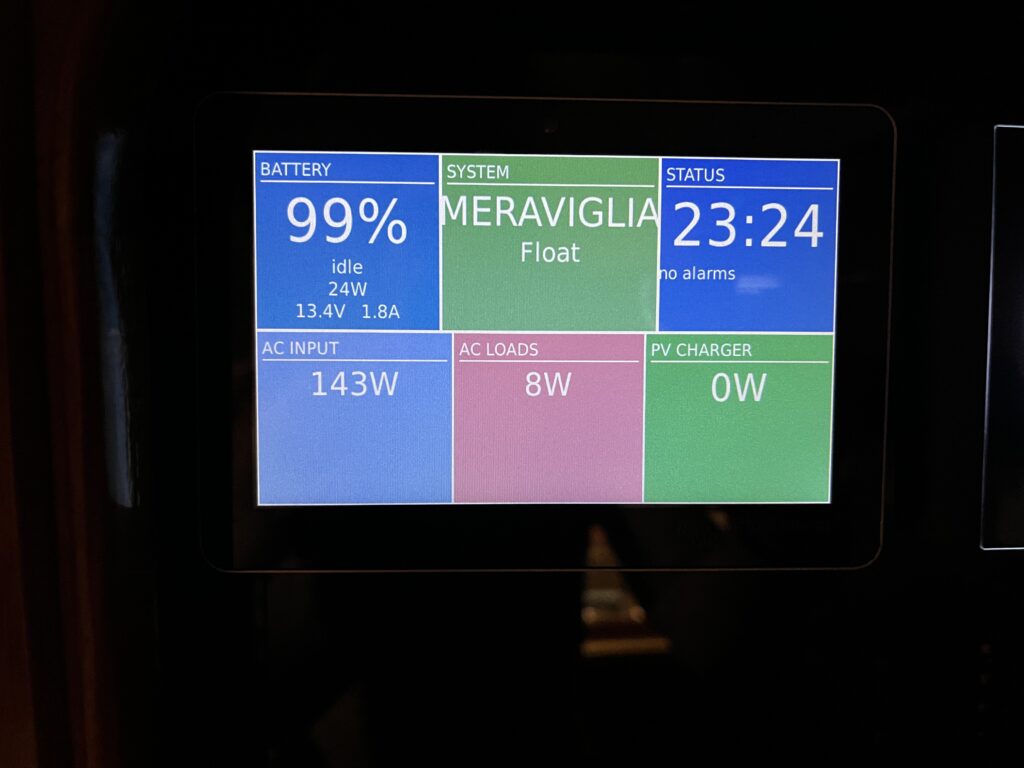

- Second, our Victron SmartShunt that is supposed to track battery charge and usage was never connected. So, we never knew that our batteries were almost dead

- Third, our battery charger was configured for lead-acid batteries, not lithium batteries. Not so good.

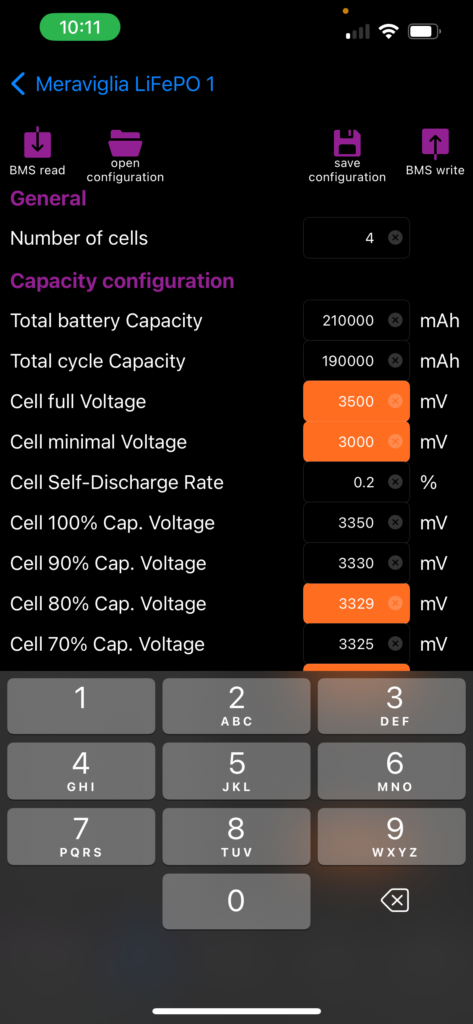

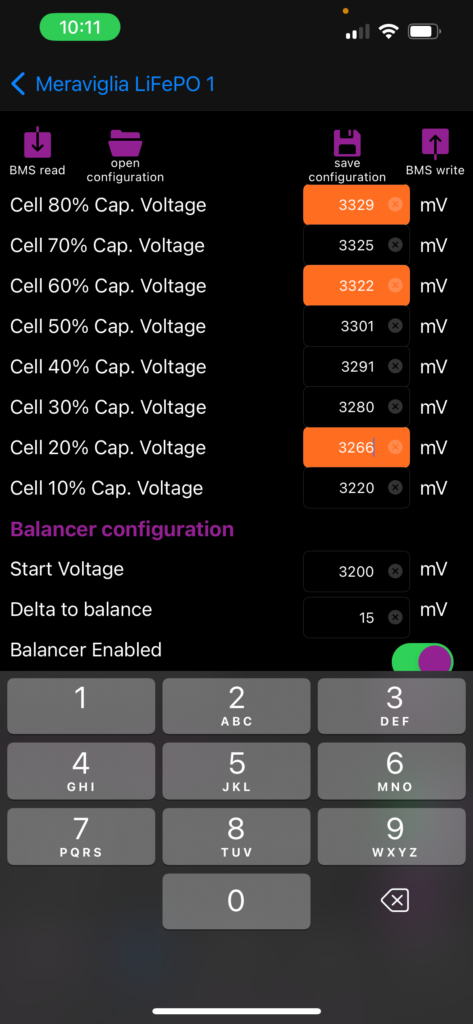

- Fourth, each of our lithium batteries was supposed to be tuned/configured before shipment. That wasn’t done, so the battery management system had no idea how much charge each battery had.

- Fifth, one of the battery management system modules was turned off. It doesn’t really work so well that way.

- Sixth, our DC-DC charger was wired incorrectly

So, obviously there was a whole bunch of badness going on there. The good news is that it was fairly straightforward to fix. We got the SmartShunt connected and corrected the charger wiring. I spend a few hours with the owner of the battery company getting the batteries correctly configured and then spent a few more hours reading/learning about our Victron equipment. After that, I was able to update all the firmware, get them all connected to one network, get them all talking to one another and get them all speaking the same language. So I THINK we now have a working system. We’ll see. If not, I’ll just keep tearing our bed apart twice day, because where are the batteries? Right.

What’s the take-home message here? I have no idea. Actually, I think there are several.

First, there is a saying that “if you wait to leave until everything is fixed, you’ll never leave”. That’s true. But it’s also true that when you have a boat that has had as much work done as ours, shaking her down is important. REALLY important. We failed to do that because we wanted to get out there sailing (did I mention it’s cold?). We left without, for instance having a good understanding of our power management system. That was a big mistake.

Second, it’s really easy to lose track of things. We have completely overhauled this boat: engine, rigging, electrical, battery, electronics, deck hardware, hatches, portlights, bilge, plumbing. We’ve disrupted/changed/enhanced/replaced every major system. When there is that much going on, sometime things get lost-like not having the SmartShunt connected. Hence the need for a good shakedown.

Third, schedules are BAD. When one is as reliant on the weather as a sailor, saying one has to be in a certain place at a certain time is a recipe for problems. We are meeting our kids in Miami for Christmas. We want to get there by boat. So we decided to go, shakedown be damned. Well, it turns out we were damning ourselves.

But the good news is that, things seem to be fixed, we seem to be back on track, and we have plenty of time to get to Miami by Christmas. But first, we’re going to go out and try to break stuff. Because that’s what we should have done to begin with. Let’s go! T-minus….I don’t know exactly.

December 7, 2023 at 6:42 pm

Would you have tackled this, if you knew about all this frustration and expense. Lol. Congratulations. You have handled it admirably. Now get out there and shake the _ _ _ _ out of it. Smooth sailing.

December 7, 2023 at 7:22 pm

One step forward, two steps back. Now shake her down and get a move on to South Beach! Hopeful for no new surprises!

December 10, 2023 at 8:12 pm

Ahhh tearing the bed apart multiple times a day to get to batteries or whatever else is under there. I feel that!

One thing we did before leaving the dock was to “unplug” to see how all the electrical systems (batteries, etc) performed. It’s a safe way to do it without being underway and being able to troubleshoot issues while at the slip.

So glad you’re getting stuff fixed and not pushing on the timeline. So hard to appreciate the journey when the journey has us sitting in one place for a long time💜