Okay, we’re not building a plastic boat, but we are REbuilding a plastic boat. And in order to repair it, we need to understand how it’s built. If you’ve been following our social media posts, you know we’ve done some destruction. Now we need to rebuild. To do that, we need to know how Meraviglia is put together. So here goes: a quick primer on plastic boats

Meraviglia is a plastic boat. Technically, she is a fiberglass-reinforced plastic boat, but they are the same. She is made of tiny strands of fiberglass (yes, that itchy stuff in attic insulation) all glued together with epoxy resin (plastic). She was built in 1985, which means there are some significant differences between her construction and the boats built today.

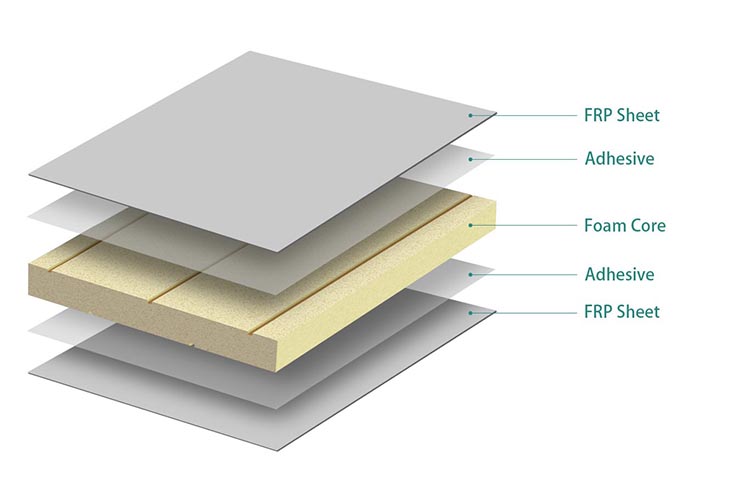

First, her hull is solid fiberglass. That means from the bottom of her keel to the top of her sheer (where the hull meets the part we walk on), she is solid, thick fiberglass. Today’s cruising boats are mostly composites. Think of their construction as being like a sandwich: there is a fiberglass layer on the inside, one on the outside, and then there is foam sandwiched in between. This means modern boats are significantly lighter. For instance, a Beneteau First 473, which is a similar size, weighs 12 tons. Meraviglia weighs in at 16 tons. That has a whole lot of ramifications on handling and performance, but that’s for a different post.

Second, our deck and cabin top are composite construction: two layers of fiberglass with foam in between-similar to modern boats. But here, there is one big difference: Meraviglia, in 1985, was made by hand: actual people laid up the fiberglass over the foam in a mold. That introduces the opportunity for mistakes and areas where there wasn’t a good bond between the layers. Today’s boats are made in molds too, but they are made by machines laying down the layers and then sucking everything together in a giant vacuum bag to maximize adhesion and bonding.

Third, boats have holes. Lots and lots of holes: hatches, portlights, chainplate fittings, deck fittings, electrical fittings, etc. Many holes. Each one of those holes is an opportunity for water to get into the boat. That’s a problem. Not for sinking, so much, but for rot and the dreaded delamination. Water can get into the foam layer between the fiberglass and cause separation. It can also leak into the boat and that leads to rot of the wood used in the interior.

And that’s where we are: we’ve got rot. Specifically, we’ve got hatches and portlights leaking in the forward head, the saloon, and the crew cabin. That leaking has caused rot of the wood around those portlights. In addition, the rot has spread to the main structural bulkhead in the boat. Bulkheads are pieces of thick wood that run across the width of the boat and are bonded to the hull and decks with fiberglass. they give the boat more stiffness, so it doesn’t twist when underway. It has to get fixed. There is a saying among surgeons that I learned in medical school: “a chance to cut is a chance to cure.” I am not sure that is true in medicine as often as surgeons think it is, but it’s true here. If we can cut out the rotten wood and replace it with new wood, Meraviglia will be good as new. But first, we have to make a mess.

July 9, 2023 at 3:51 pm

I’m exhausted just by reading all the time, effort, and energy (&$) that you both have expended so far. However, the bonding process, human, and fiberglass , is priceless!