That’s right. We’re preppers. Though not, admittedly, in the traditional sense. No underground bunkers. No heavy weapons. No zombie killing weaponry. Though we are going heavy on solar power and canned goods.

We are now back on board Meraviglia in Panama after a wonderful 2 1/2 weeks in Georgia for the holidays with family. And we are in full-on prep mode for crossing the Pacific Ocean. Admittedly, we aren’t going ALL the way across in one jump. We are headed to French Polynesia, which is “only” half way: 4,000 nautical miles. It should take about 28 days. That’s 28 days on the open ocean. If that makes you swallow hard, you’re not alone.

Preparation is the key, so we are hitting it hard. We started by bringing about 90 lbs. of boat parts back from the States. Filters, fuel sensors, a spare starter motor, steering cable, lighting, water pumps, propane ignitor switches, hull anodes, windlass gears. It was a lot of stuff. I don’t think the baggage handlers were probably very happy.

We’ve got a long list, as you can see. But in the week and a half that we have been back, we’ve managed to get quite a few things checked off already. We ripped out the galley sink drain plumbing-it was still original and I finally figured out that it was the source of the leaking water in the bilge (well, one of the sources anyway). Turns out the stainless steel T-fittings were corroded through After replacing those and the hoses, we seem to be dry. I also replaced the broken jaw end on our whisker pole. It broke back when we sailed from Grenada to Bonaire. I had jury-rigged it to get to Panama, but now it is actually fixed for real (I’ll try not to break it again-don’t force things, Bob). I also fixed the boom vang, which broke months ago. The pad eye on the boom had failed. The new pad eye is slightly beefier than the old one!

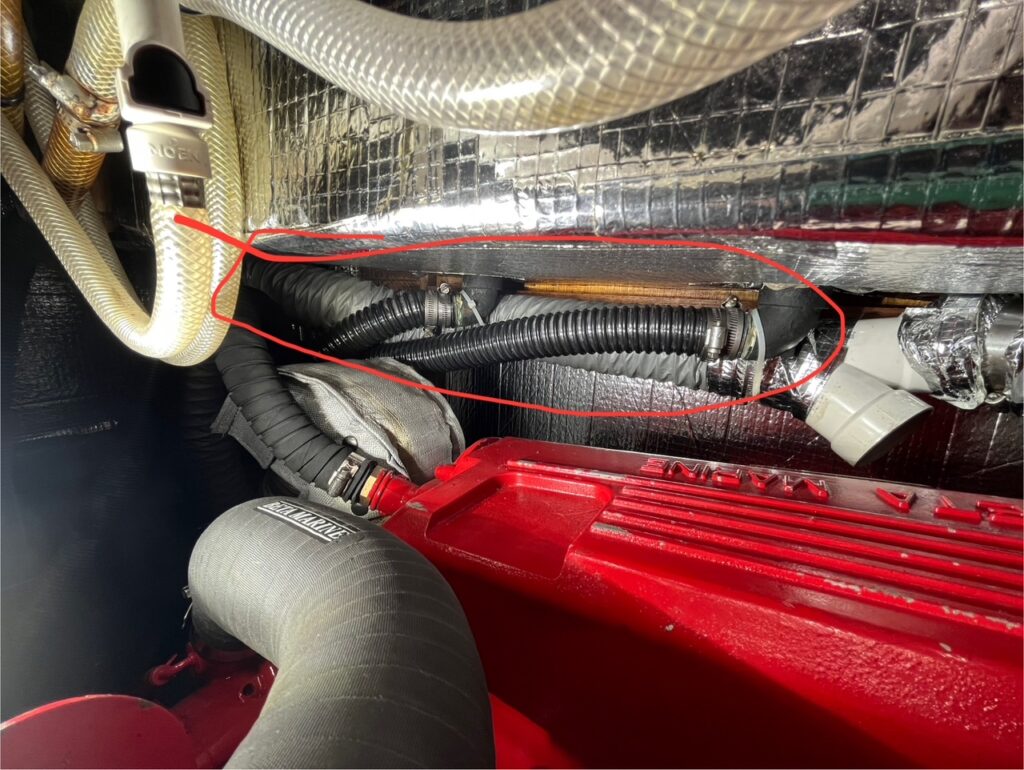

We also did some engine maintenance. The impeller for the raw water pump should be changed annually, so we did that. This resulted in a very unpleasant surprise. The impeller was almost totally destroyed. That’s…bad. No impeller means no engine cooling. Again, bad. I expected the impeller to be fine. Not so much. The thing with impeller failure is that it means one has to be a mechanical archeologist. Where did the pieces go? Are they clogging up other parts of the engine? So more disassembly was in store. We found all the pieces lodged in the heat exchanger for the transmission. Several hours later, we had a new impeller installed, miscellaneous bits found and removed, and the engine reassembled. It runs and, surprise, the water flow seems MUCH better! Happily, we never had any engine overheating issues, so I think there is no lasting damage. Our best guess is that we damaged the impeller when we ran the engine at idle for a while with the water intake closed-oops! That was months ago. We’ll try not to repeat that performance.

I’ve also done a bunch of mast work. When we returned from the States, we noticed that the masthead VHF antenna was gone. After going aloft to take a look, it turns out the whip came unscrewed (Something came loose! Who would have thought?!). That was a pretty easy job to replace. I also scrubbed superficial corrosion from the masthead fittings, seized some shackles, tightened the upper shrouds, and replaced a spreader light. Whew!

We’ve still got a bunch to do, but we’re off to a good start. We’re still targeting departure in late January/early February. I’ll let Kim handle next week’s post-all things provisioning.

Now, back to the list!

January 12, 2025 at 3:01 pm

WOW!! What an adventure. I’ll be praying for safe sailing in the Pacific for you.

January 12, 2025 at 9:51 pm

Thanks! Much appreciated.

January 12, 2025 at 3:19 pm

Incredible. Both of you are well equipped with your training to plan for any possible emergency but then wing it when it was not on your plan. Here’s to some smooth sailing ahead!

January 12, 2025 at 9:51 pm

Thanks, Madam President! We hope 2025 is the year we see you in person!

January 12, 2025 at 3:53 pm

When antenna is all gone, you must whip it.

January 12, 2025 at 9:51 pm

Devo! Strangely not on my playlist!

January 12, 2025 at 5:57 pm

Need to add to your list:

Take 10 minutes to relax!!

January 12, 2025 at 9:50 pm

Agree!

January 13, 2025 at 2:22 pm

Will that be 28 straight days on your 4 hour shifts 24 hours a day?!

January 13, 2025 at 4:32 pm

Correct. It sounds bad when you say it like that.

January 16, 2025 at 3:45 pm

That sounds brutal no matter how you say it.