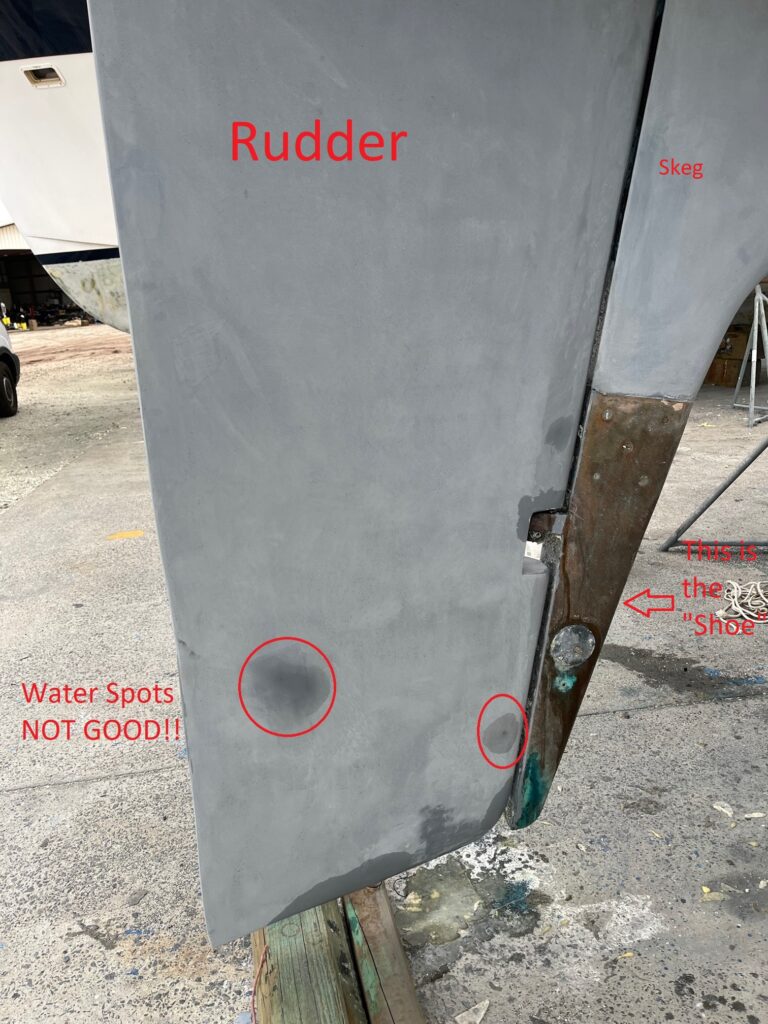

Can we talk about our rudder? Because it’s a royal pain. As the boat sat on the hard, it became clear that the rudder was “wet”. Namely, it was leaking water. Closer inspection revealed that the trailing edge was delaminating and allowing water inside. Our rudder is essentially two pieces of fiberglass around a piece of foam. That foam, when it gets wet, holds onto the water. Thus the leaking.

We needed to fix that for sure. So, the yard crew ground the rudder back to good fiberglass. When they could find it. In the end, they had to remove half of the rudder, exposing the foam. Once the foam had dried out, they rebuilt that side of the rudder, epoxied it, and applied the barrier coat. Problem solved.

Nope.

Soon, wet areas appeared in the barrier coat. More grinding, more exposing foam. More drying with a heat gun. More rebuilding. Problem solved.

Nope.

Wet areas kept appearing. “Bob, we’re going to need to drop the rudder.”

Of course we are. Because there is probably a crack or hole on the top edge of the rudder. Rainwater is coming down the side of the boat, along the bottom, dripping onto the rudder, and finding its way inside.

Sigh.

Off the rudder came. And this is where it got really ugly. The first thing that had to happen was that the “shoe” (a metal sleeve over the bottom of the skeg) had to come off.

Step One: Remove the bolts-all corroded

Step Two: Slide off the shoe-that wasn’t a problem. It basically fell off because there was pretty much nothing holding it on.

The bottom of the skeg was basically gone. At some point, Meraviglia had suffered a serious impact to the rudder and skeg. And the repair was, shall we say, inventive. Rather than rebuild the skeg with fiberglass, they filled the shoe with 3M 5200 Marine Adhesive, slid it back on what was left of the skeg and rebolted it. That would need to be rebuilt. Oh, and the metal shoe had a big crack in it.

As for the rudder, we could now see the top edge. Again, “inventive” repairs. The rudder had also been damaged. It had been repaired with Bondo automotive epoxy, which of course had failed. Hence the water in the rudder. And, as they removed the rudder, the flange that lines the opening in the hull came off with the rudder because it was corroded to the rudder post. Ummm, yeah-that’s supposed to be attached to the boat. Sigh. Old boat problems.

So, in order to re-mount our rudder, we would need to:

- Rebuild the rudder (disassemble it, dry it out, replace the center foam, close it up, and re-fiberglass it

- Rebuild the skeg with new fiberglass

- Repair the shoe-it had a large crack in it that needed to ground out and re-welded with new metal added

- Machine a new flange and reattach that to the hull.

- Rehang the rudder.

Would she EVER float again? We were beginning to wonder. Our wallets were certainly a lot lighter.

UPDATE: The rudder was rehung on Friday, June 23rd! Success!

June 25, 2023 at 3:27 pm

Oh my, you’ve had quite the adventure already with your feet still on terra firma!

June 26, 2023 at 10:24 am

Indeed we have!

June 25, 2023 at 6:21 pm

Wow! Sure hope you two really enjoy sailing after all this. We’re praying for you. John & Marsha Johns

June 26, 2023 at 10:23 am

Thanks!

June 25, 2023 at 10:16 pm

I’m beginning to think you’ve probably left a comment or two on your boat inspector’s yelp page by now. And maybe aren’t planning on sending Christmas cards to the prior owner.

June 26, 2023 at 10:23 am

Those thoughts have occurred…

June 25, 2023 at 10:31 pm

I would have given up by now. Seems like whoever sold you this boat were not upfront with all the issues it had/has. Good luck hope all the problems are behind you and it’s smooth sailing from here on.

June 26, 2023 at 10:22 am

So do we! However…

June 26, 2023 at 1:11 am

Truly some tough times but nothing can compare to the pure joy of sailing. You’re hard work will pay off and it will bring you many adventures. You’re making it happen and we are all inspired by your hard work and determination. You can truly say you know your boat inside and out. Best wishes. Thanks for bringing us on this journey.

June 26, 2023 at 6:36 pm

Can’t wait for the Netflix documentary of this story!