We need a new motor. And transmission. Because of course we do-it’s really the only system we haven’t replaced. So it failed. Away we go!

Removing a 750-odd pound engine from a sailboat at dock is not straightforward (no surprise there). The engine sits about at the level of the waterline. The deck sits about 3 feet above the waterline. The hatchway sits about 6 feet above the waterline. And there is no crane. Preparation is key. Kim and I removed the dodger and front part of the bimini from over the companionway hatch. We also removed the saloon table and the companionway stairs (we entered/exited via the hatch in our cabin). Then we removed the manual bilge pump and the fuel filter cabinet from the engine compartment. We also laid non-skid in the saloon. We were ready.

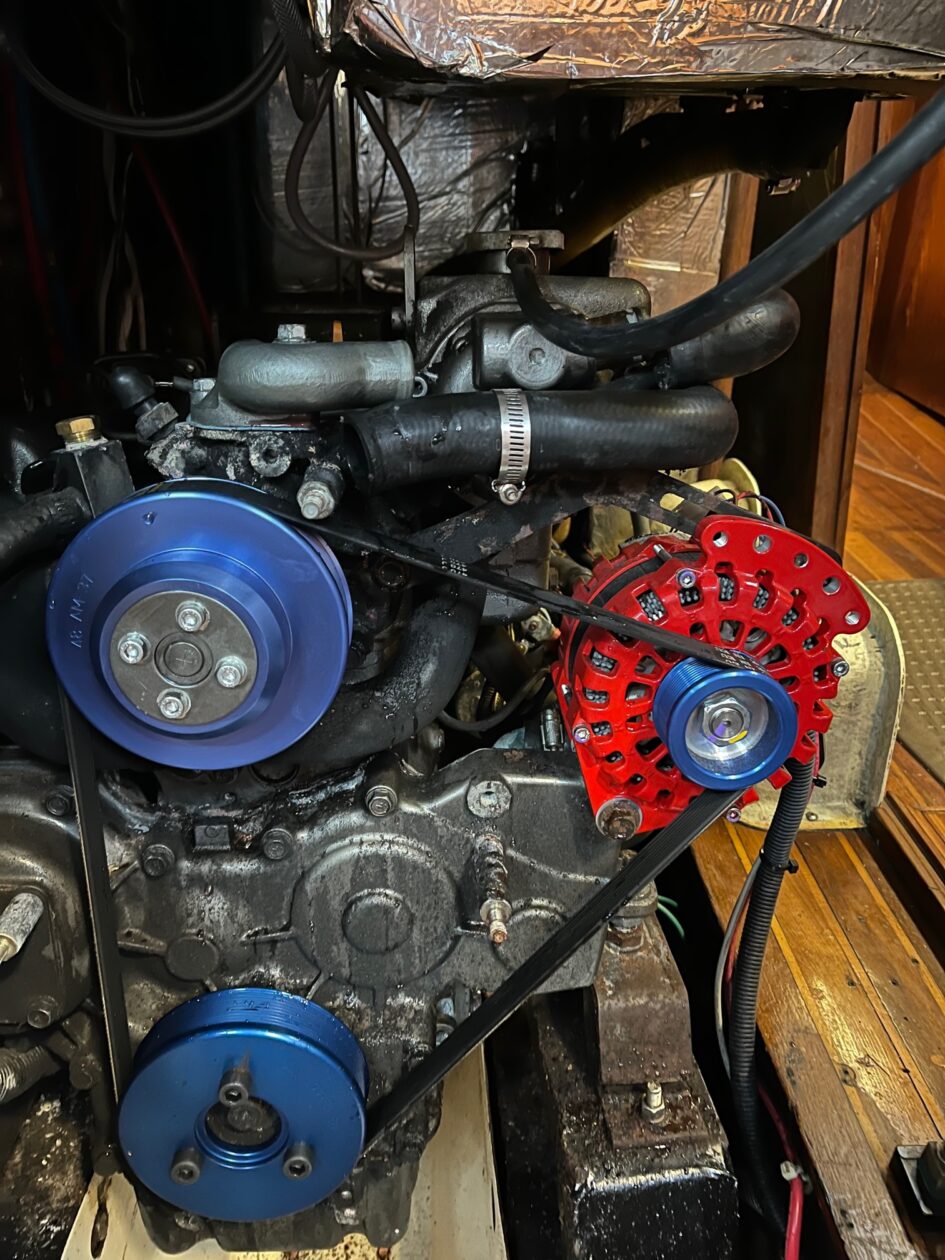

Our team, Drew and Daniel showed up bright and early and away we went. They started removing stuff from the engine to make it easier to move/lift: transmission, bell housing, flywheel, heat exchanger, fuel filter, alternator-if it could come off, it came off. Kim and I handed them tools and removed belts and pulleys and unfastened the engine mounts. Next up, they erected a gantry over the companionway and attached a chainfall. With the chainfall attached to the engine, we lifted, scooted, nudged and pried it forward out of the engine compartment. Then up it went and out of the boat-pretty simply really. Once it was in the cockpit, we moved the chainfall to the boom of the boat, hoisted the engine into the air, swung it over to the dock, and lowered it into a cart. Done! It only took about 4 hours.

Of course, then Kim and I spent the next day and a half dealing with the aftermath. Namely, 38 years of accumulated grease, dropped parts, forgotten hoses, dust, dirt, engine oil, transmission fluid, and coolant that had been sitting under the engine. It was, honestly, the nastiest mess I’ve ever encountered. I’m a pediatrician. Vomit? No problem. Diarrhea. No biggie. THIS was nasty. It took a day and a half with heavy duty degreaser, scrub brushes, and toothbrushes to excavate our way to the bottom. We then spent an hour cleaning the stuff we used to do the cleaning. Next up: we pulled all the legacy hoses, wiring, and connectors out of the engine compartment and organized the remaining wiring. DONE!

Well, not really. We need to paint it and replace the soundproofing/insulation. But then we’ll be ready for our new engine! We anticipate installation in two weeks. In the meantime, another major project has cropped up. More about that later.

January 4, 2024 at 1:35 pm

Impressive work guys!

January 4, 2024 at 3:51 pm

Wow. Incredible clean up job guys. it will look great after it’s painted. All we can say is, just think about how great it will be when you are sailing around the Caribbean islands.

January 4, 2024 at 4:34 pm

With all the trouble that engine has caused you, I’m surprised you didn’t boom it over the starboard side and send it to a well-deserved death in Davy Jones’s locker.

January 5, 2024 at 12:16 am

There’s a rumor it can be sold… We hope.