In high school, because I was planning on a career in medicine, I was in all the high-level classes: AP Biology, AP Chemistry, AP Physics, Pre-Calculus. Yep, I was a nerd. But there was one class I took that I have thanked God for over and over. Yep. Typing. I use that skill almost every day. Not having to hunt and peck has saved me a ton of time and frustration. Recently, Kim and I spend a week taking classes at Cruisers University in Annapolis, Maryland. I took a bunch of classes there: weather forecasting, dinghy and outboard motor use, heavy-weather sailing, ocean waves and currents, knot-tying. And you know what I think is going to be the “boaty” equivalent of typing? Diesel Engine Maintenance. I spent two full days at Cruisers U. staring at diesel engines, taking apart diesel engines, looking at broken diesel engines… You get the picture. This week, those skills suddenly were put to use. Because… it is “Engine Week”.

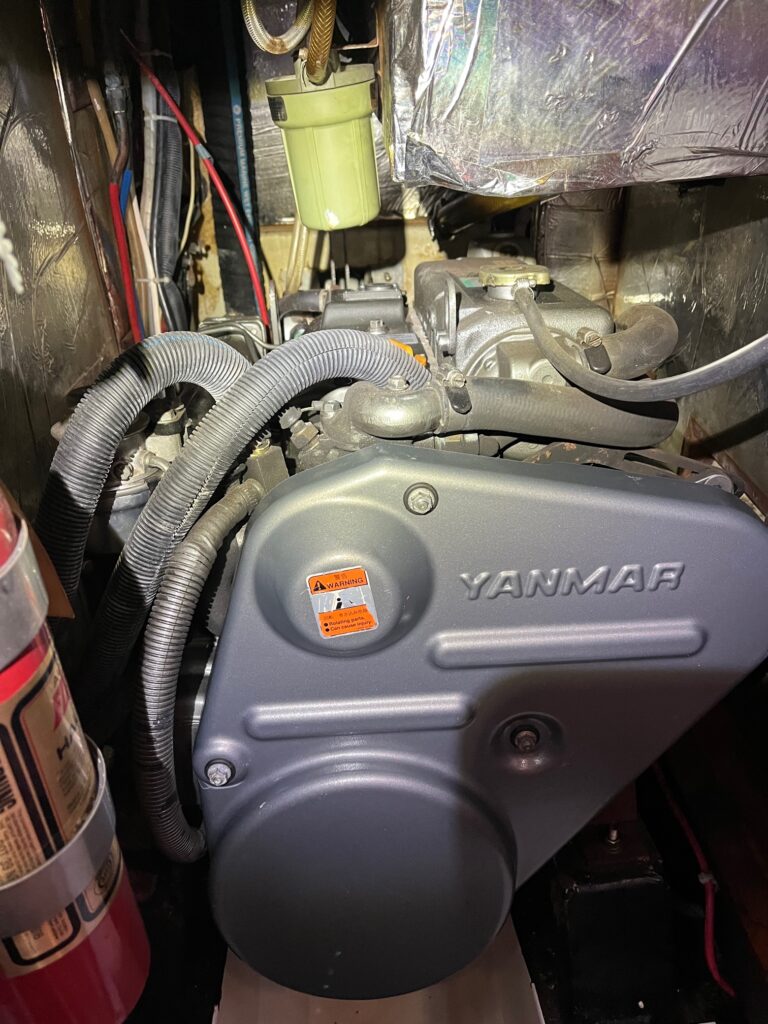

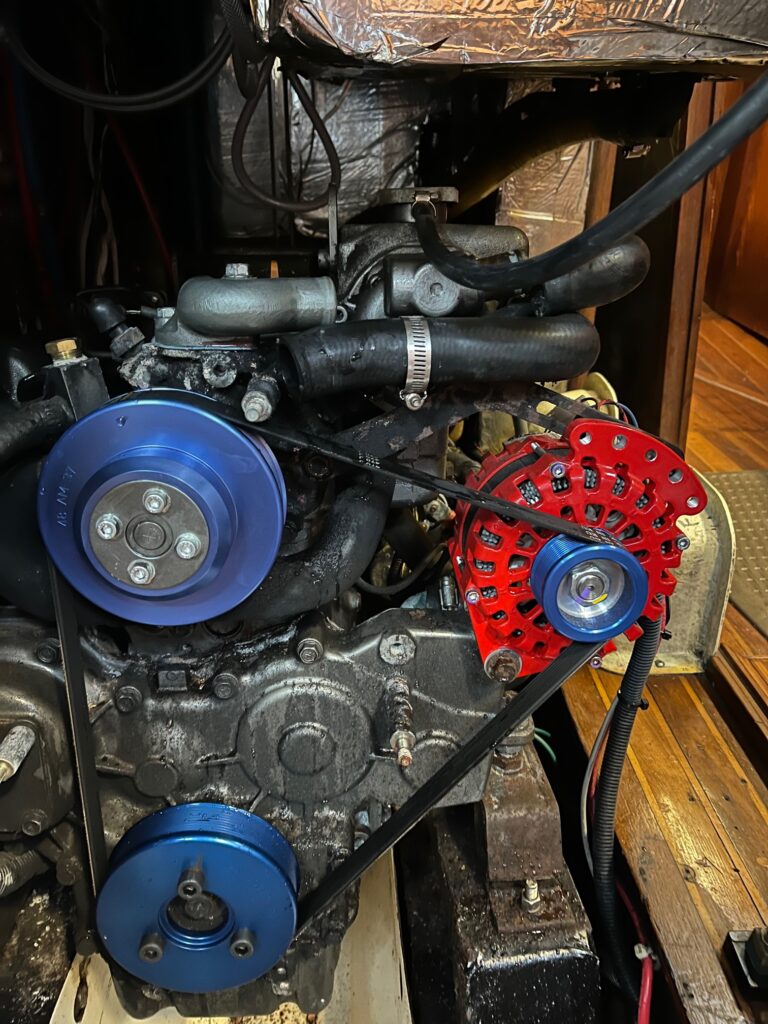

Our engine is the only piece of equipment on the boat that we haven’t ripped apart because it basically seemed to be running fine. But the diesel class taught me (well, REINFORCED, really) that preventive maintenance is key. So off I went into the engine compartment. First stop was the cooling system. I took off the mixing elbow, where exhaust gasses and exhaust gas combine and are pumped out of the boat. Because a marine diesel is partially cooled by seawater, the elbow can corrode. I got it apart and, hooray!, it was not corroded. I quickly put it back on. Then I took apart the heat exchanger. This is where coolant from the engine transfers its heat to the seawater. Again, it can corrode. Ours did have a bit of ocean debris in it, but no corrosion yet. We sent it off to get an acid bath and it came back good as new. Next up was the coolant pump. The bearings on that were starting to go, so we replaced it. Secondary fuel filter was also corroded-replaced that too. I changed the filter on the primary fuel filter and it was fine (whew!).

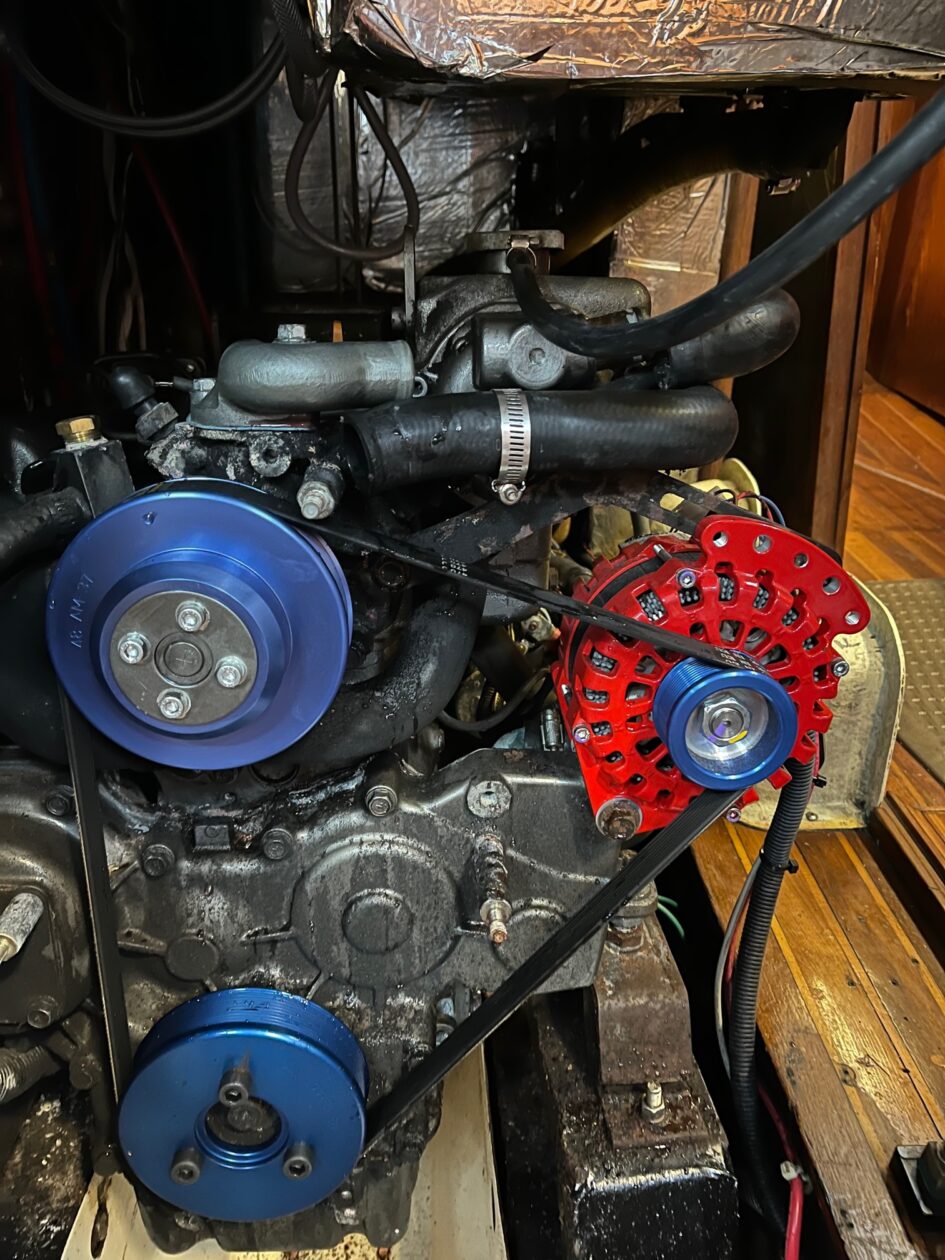

Our project manager also said I should “show the engine some love”. So I did. With a wire brush, toothbrush, and engine degreaser. THAT was fun. After removing the corrosion/rust, I primed and painted the engine block so it looks shiny! Who knew “Yanmar Gray” is an actual paint color?!

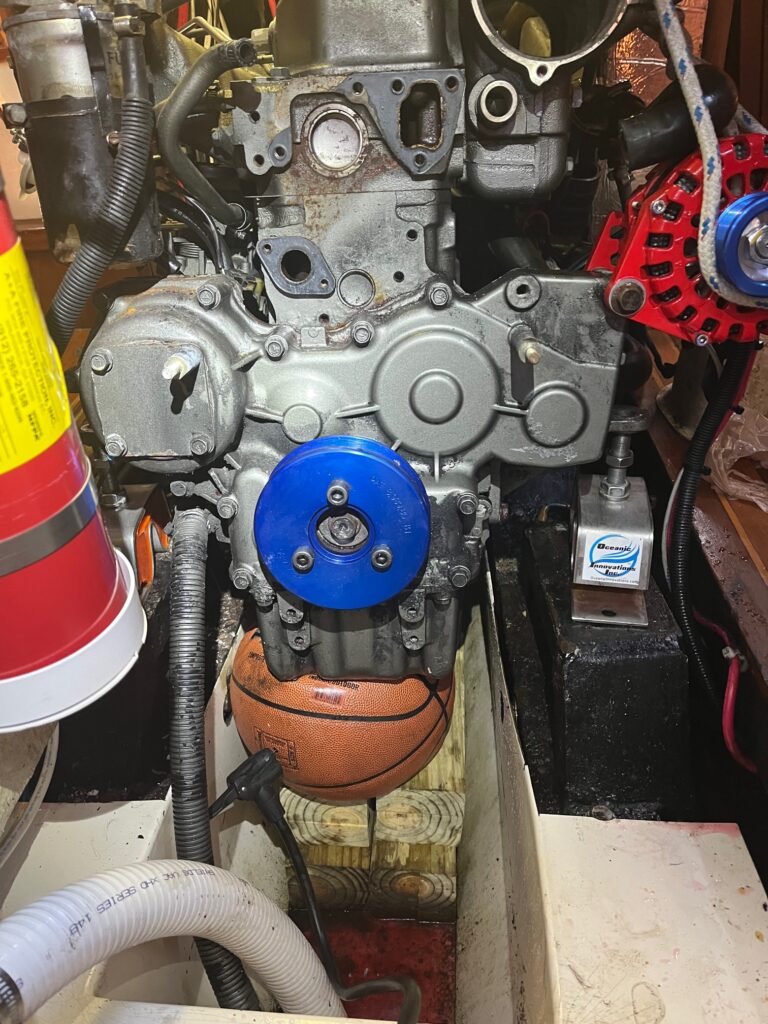

Last, but definitely not least, were the engine mounts. These are what connects the engine to the boat-kind of important. Ours were pretty badly rusted (likely from when she sank in 2020) and also starting to collapse. We needed to replace them. So I channeled my inner Michael Jordan. Yep, I played basketball. Well, actually I played WITH a basketball.

In order to change the mounts, the engine has to be lifted so the old mounts can be removed and the new mounts put in place. To do the lifting, I used the basketball. It turns out that a 500 lb. diesel engine can be easily lifted by putting a deflated basketball underneath it and using a hand pump. Seriously. Really easy. A few hours later, we had 4 new engine mounts.

So, I have now quickly put to use some new skills-that I never thought I would have or need. I’m feeling a little accomplished. So something will break..

November 3, 2023 at 12:12 am

Wow!! That first basketball picture was a bit confusing……..now I understand!!! Very clever!!!

November 3, 2023 at 11:44 am

Thanks!

November 3, 2023 at 12:20 am

Sank?! I thought it was a water intrusion event.

November 3, 2023 at 11:44 am

Potato, potahto…

November 3, 2023 at 1:35 am

The basketball trick is impressive, Bob!!!

November 3, 2023 at 11:44 am

Thanks!